Consultation, Cooperation & Coordination CoP

In this 30-minute session, we look at the Consultation, Cooperation & Coordination Code of Practice (CC&C CoP). We cover the Commonwealth and Model versions of the CoP, appendices & a summary of detailed requirements; and further commentary. This CoP is one of the two that are generally applicable.

https://youtu.be/CARK4tJnX28

This is the three-minute demo of the full, 30-minute video.

see the full-length video here

Consultation, Cooperation & Coordination CoP: Topics

- CC&C in the Federal or Commonwealth CoP;

- Extra CC&C in the Model CoP;

- (Watch out for Jurisdiction);

- Further commentary; and

- Where to get more information.

Consultation, Cooperation & Coordination CoP: Transcript

Click Here for the Transcript

Consultation, Cooperation & Coordination CoP

Hello, everyone, and welcome to The Safety Artisan. I'm Simon and today we're going to be talking about a very useful subject, which is Codes of Practice. And one Code of Practice in particular, which is the Code of Practice for Consultation, Cooperation and Coordination. And it doesn't sound like the most exciting subject, I'll admit, but this is one of only two Codes of Practice that you must be aware of if operating in Australia, or exporting to Australia, or importing stuff to Australia, whatever it might be. The other Code of Practice that you must be aware of is the Risk Management Code of Practice. There are a lot more Code of Practices than these two, but they don't always apply. So, I mean if you're not doing anything to do with asbestos, you don't have to worry about what it says in the Asbestos Code of Practice. But this one you do because it applies to everything.

Topics for this Session

And I've used this Code of Practice to help clients and to do particular things and help everybody understand what we have to do, and it’s very useful. And in this session, I will be explaining how to get the best out of this Code of Practice and, at the end, where to get more information. So, I hope you'll find that useful. So we're going to be talking about the - I'm just going to call it the C, C & C CoP for short because it's a dreadful mouthful, isn't it? We're going to be looking at the federal or Commonwealth Code of Practice and then we're going to look at some extras in the Model Code of Practice. So just to explain that briefly, the Model Code of Practice is on the Safe Work Australia website, and that is the Model from which all other CoPs are developed. However, Safe Work Australia is not a regulator. So individual regulators and the example I'm using is the Commonwealth one- or Comcare, as it's known- they have chosen to edit the Model CoP and change it and remove quite a bit of material. Now, why they chose to do that, I do not know. So, you have to be careful which jurisdiction you're operating in, in Australia. If you are in a Commonwealth workplace, then you need to apply the Commonwealth or the federal version of WHS, including this CoP. And if you're in a state or territory workplace, or a commercial workplace in a state or territory, you need to apply the relevant one there. And just to complicate matters, Western Australia has not yet introduced WHS and Victoria has no plans to do so. So, of course, in Australia, we like to make life simple for ourselves, don't we? Oh no, we don't!

So after I've gone through some basics of what's in the CoP, because you'll see there's an awful lot of material in there that I'm not going to talk about. I produced some commentary that I think you will find helpful and where to get more information, as I promised. So, let's get on with it!

When to Consult

So, first of all- and you'll notice that I'm only including those bits really that say when you must do something. So, this is quoting Section 49 of the WHS Act, which says that if you're conducting a business or some kind of undertaking- so it's not just a commercial business, but anything- you must consult with your workers when identifying hazards and assessing risks, making decisions about how you're going to control those risks, making decisions about the adequacy of facilities for welfare, proposing changes that affect health and safety, and making decisions about procedures for consulting with workers, providing information and training, and so on and so forth. So, there's a whole raft of things that you have to consult your workers on. So, this is all workplace so far. Now, in my role as a safety consultant, I'm often working with people who are introducing they're buying bits of kit, or designing or importing bits of kit, and there is no work yet, so there's no workers. But we always try and get a representative of the end-user involved because that really does help you do good quality safety work and avoid- to be honest- wasting time and money on things that are theoretically possible or theoretically sound problematic but in reality, it just doesn't arise for whatever reason. So, I really do recommend getting those end-user representatives involved.

Effective Consultation

And if we go on to Section 48- for some reason, the cop quotes these things in reverse order- to be effective in consultation, we require information to be shared. Workers have got to have a reasonable opportunity to express their views. They've got to have a reasonable opportunity to contribute to decisions. Their views must be taken into account and they must be advised of the outcomes of consultation. So, all good common-sense stuff, I would think. Nothing controversial about this and that- to be honest- that's a feature of CoPs. They tell you to do things that you think, “Yeah, I really ought to be doing that!”.

Consultation Procedures

Continuing with the countdown, we're on to Section 47. Consultation procedures, again more basic common sense. If you’ve agreed to procedures for consultation, you must follow those procedures. It's not rocket science, is it, folks? Let's move on.

Sections 16 & 46

OK, now this is a bit more interesting, I think. This is getting into the real guts of this Code of Practice because where consultation, cooperation and coordination really come into play is where you've got multiple stakeholders, multiple duty holders- that is to say, those with a duty to protect the health and safety of people. Where multiple stakeholders, duty holders, have to get together and work together in order to come up with a solution. So the law says- Section 16 says where more than one person has a duty for the same thing, for the same matter, each person retains that responsibility. You cannot wriggle out of your responsibility just because you only control a bit over here and not over here. So, the two duty holders who have control here and here, they have to work together. The law says so. And so this is really the guts of this Code of Practice. And they must work together to discharge their duties to the extent to which they can. And the extent to which you can is the extent to which you influence and control the matter. So, WHS law is very big about control. If you have control of the bit, you've got to do your bit and you must work with people who have control of other things. You might be designing or buying a piece of kit. Other people might control the workplace. There might be another group of people who represent the operators, and then another group who represent the maintainers, and so on and so forth. They've all got to be involved if they're relevant to managing risk. And of course, as risk in WHS is cradle to grave, then pretty much everyone is involved.

So, Section 46, and in these situations where you have got multiple duty holders, each person with a duty must, so far as is reasonably practicable, consult, cooperate and coordinate with all other persons. And I'm going to do a session quite soon on so far as is reasonably practicable, or SOFARP, and in it, I will tell you that SOFARP is an objective test and the law sets objective expectations for what a reasonable person would do. So, you can't just say, “Well, I'll decide what is reasonable or not reasonable.”. The law has already done it for you and there's guidance out there to help you so follow it. So, we will do something on that guidance, about what is reasonable and what is reasonably practicable. But we've got to work with each other SOFARP. For the greater good! Sorry, that's a quote from one of my favourite comedy films, by the way.

CoP Appendices

So, appendices to the CoP. If we look at the appendices in the federal or Commonwealth CoP, there are only three. So, they've got some examples of arrangements. They've got a consultation checklist, and they've got an appendix on C, C and C activities, which is all good. That's all good stuff. In addition, if you go back to the Model Code of Practice, you will find that there's also a glossary. Yes, they've got the consultation checklist. And then in Appendix E, you've got a summary of all the consultation requirements in the WHS regulations, which is really useful. So even if in the CoP that applies to you, your version of the CoP doesn't have the appendix, I would recommend going and having a look in the Model CoP. And if you're not aware what you got, if you've got a high-risk business, then you're going to find some extra requirements in the regulations. So, I would go and have a look at Appendix E if you're doing anything that could kill one or more people. So, if you're dealing with more serious risks, then I would go and have a look at that just to- as a good lead in to the regulations. If you already know the regulations backwards, then great, you don't need to bother. But there are over 600 regulations in WHS, so it's always worth checking up to make sure you haven't missed anything.

Extras in the Model CoP

We've kind of started already, but now we've really started we're going to talk about the extras in the Model Code of Practice.

Further Duties of PCBUs

In the modal Code of Practice, we get a reminder that designers, manufacturers, importers and suppliers have got safety responsibilities to ensure, so far as is reasonably practicable, that the plant's substance or structure that they are designing, etc, etc, is without risks to health and safety. And they've got a duty to carry out testing and analysis and to provide specific safety-related information about plant or substance. So there's a good reminder in there that we all, wherever we are in the supply chain, we've all got these responsibilities. And to assist in meeting these duties, the WHS regulations require manufacturers to consult with designers, importers to consult with designers and manufacturers, and whoever commissions construction work to consult with the designer of the structure, for example. There's a lot of useful extra pointers in the Model Code of Practice, which may not be in the version that, technically speaking/strictly speaking, you have to follow. So, worth a look.

Officers (of the PCBU)

And then there's also a reminder to officers of the business or undertaking. Basically, officers says- for example, company directors, those kinds of people, have a duty to exercise due diligence. And you have to go look at due diligence to see what that is. There are basically six bullet points in the act that describe due diligence. Again, it's all good common-sense stuff. There’s nothing esoteric in there or objectionable. And that due diligence includes taking reasonable steps to ensure that you've got appropriate processes for complying with the duty to consult as well as to duty- with workers sorry, as well as consulting, cooperating and coordinating with other duty holders. And there's further guidance on what's an officer in that interpretive guideline and under Section 27 of the law.

Principal Contractors

And then here is one I picked out. I've not got all of the requirements, but here's a useful one. There’s a particular regulation, number 309, that says if you're doing construction work the principal contractor for a construction project has a specific duty under WHS regulations to document in their WHS management plan the arrangements for consultation, cooperation and coordination. Now that's not unique, as we've just seen, to construction, but there is a specific requirement in there for a principal contractor. And WHS assumes a particular structure where you've got a prime contractor, or a principal contractor, who is leading the construction for the customer. So, have a look at that. There's also a CoP on the construction of structures so if you're in that game you'll find that useful too.

Major Hazard Facilities

And then I've got one slide on major hazard facilities. Now, a major hazard facility, strictly speaking, is a facility where you've got enough of a dangerous chemical- and it might be flammable, it might be toxic, it might be explosive, whatever it is. There's a whole list of chemicals in the regulations and it says if you've got so many tons of this or that, you've hit the threshold and you are operating a major hazard facility. There's a whole raft of extra regulations that apply to MHFs. And it says, for example, regulation 552 requires a major facility- sorry, a major hazard facilities safety case outline- so a safety case report by another name- to include a description of the consultation with workers that's been undertaken in the preparation of the safety case. Again, you've got a very specific requirement to consult with workers and to document it. Which, interestingly enough, generally, you don't have a duty to do that. It's not mandatory to document consultation. It's recommended. It's a good idea but you don't, strictly speaking, have to do it unless you're operating an MHF. And as it says there, there's a whole bunch of regulations that cover consultation about MHFs. But as I said, if you look at Appendix E of the Model Code of Practice, it's got them all listed, which is very helpful.

Detailed Requirements

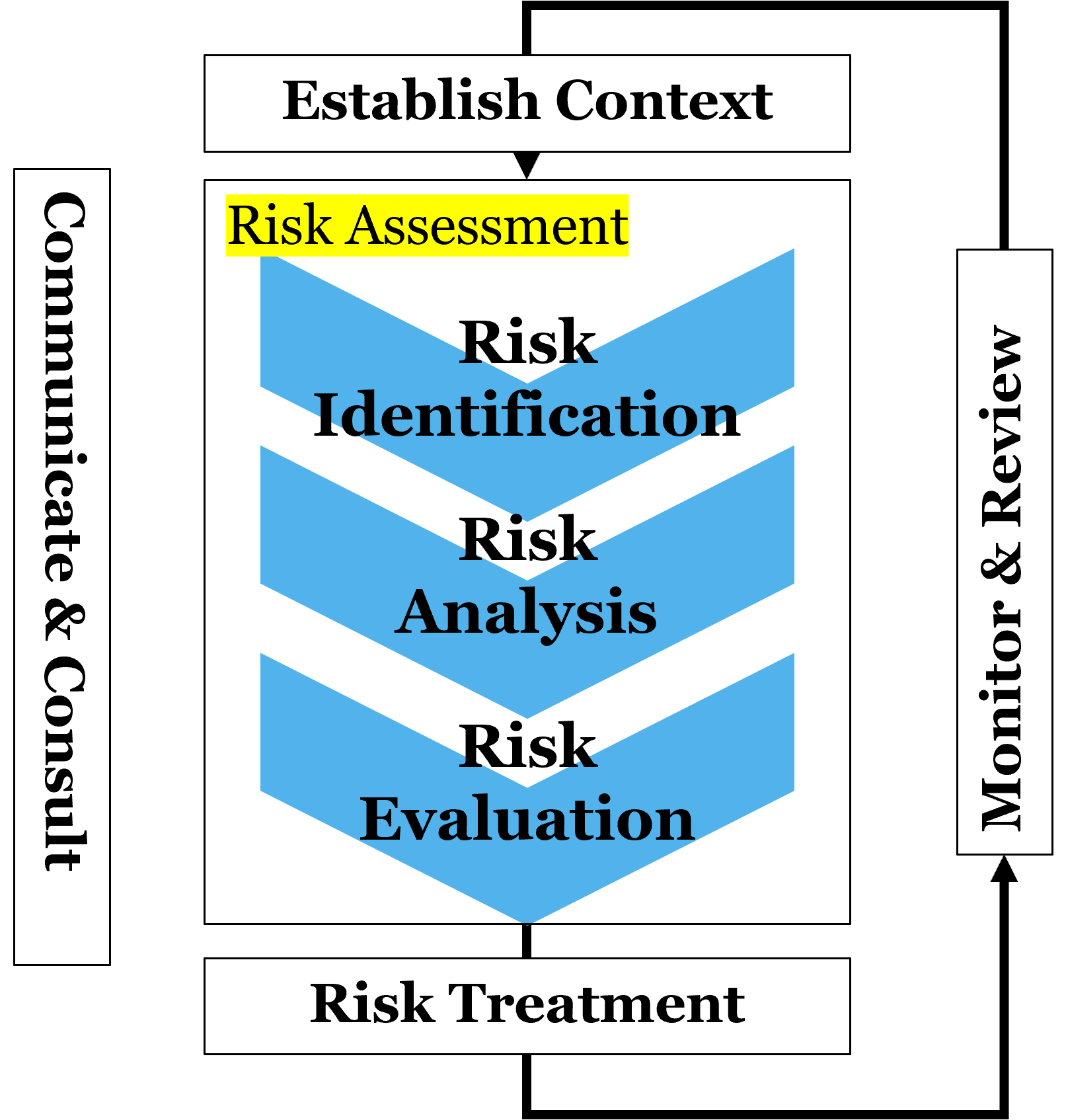

A quick word about detailed requirements. Every Code of Practice contains detailed requirements that follow this formula. So, there are three words that indicate a legal requirement that must be complied with. And those three words are ‘must’, ‘requires’- or variations on that word-, and ‘mandatory’. So, any instances of those words- Probably not always, because they occasionally you come across a usage of ‘must’ or ‘requires’ where you go “Actually, that's just an English use-“ (if you know what I mean)- “That’s just an English use of those words! It’s not really indicating a mandatory requirement”. But most of them do. So, in the Commonwealth Code of Practice, we have 41 instances of ‘must’. So, you've got to comply with those. You have 46 instances of ‘require’ and you've got to comply with those by law. Now, interestingly, in the Model Code of Practice, those numbers go up to 71 and 58, respectively. So, there're a lot more requirements in the Model Code of Practice. So, again, do make sure you've got the right Code of Practice that's been issued by the regulator for your jurisdiction. Because otherwise you might miss something you need to comply with or you might be complying with something that, strictly speaking, you don't have to. Although, of course, it's not a bad thing to do that but you don't have to.

Then there's the use of the word ‘should’, which is a recommended course of action, and ‘may’, suggests something that is optional. And again, in the Commonwealth Code of Practice, there are 62 instances of ‘should’ and 86 of ‘may’. Although I note that one of those instances of may, at least one, refers to the month of May when that Code of Practice was published. So, you've got to go through and make sure that they are relevant. And then it's slightly more in the Model Code of Practice. It’s 66 and 90, respectively. But the difference is not so great for the mandatory stuff. Now as I've said before, and in the risk management Code of Practice, my advice to you is you must comply with ‘musts’ and ‘required’s. ‘Should’ is recommendation so I would suggest complying with that unless you've got a good reason not to. In which case, I would document the fact that you've got a good reason not to and why you're not going to. And then ‘may’ is optional. You can do it if you want to and you can record the fact that you've considered those things and reject them if you want to but they are only options. So, I think there's- effectively we've got three tiers here. We've got ‘must comply’, ‘recommended’, and ‘you can do this if you think it's a good idea’.

And so the comment at the bottom, CoPs are not huge documents that typically a few tens of pages long. They will repay careful reading because you do have to comply with quite a lot of stuff that's in there and that's very clearly signposted, by the way. And also, of course, this particular Code of Practice is very useful for safety management plans. If you've got to write a safety management plan and you want to know what you have to include in it, then look in this Code of Practice and look in the Risk Management Code of Practice and make sure you include everything that is mandatory or ‘must’ or ‘requires’ and look at all the other stuff as well. And why not? If the copyright permits you to do so, which it usually does- not always, but usually. If the copyright permits you to do so and just copy and paste the stuff into your plan and then you know that you've got what you need. Then you can change the wording if you need to. But it will save you a lot of bother if you've got to write a safety management plan. It'll help you to make sure you've got everything you need to and it will save you a lot of effort. So, I recommend that I've done that myself.

Commentary #1

I think I've just got a couple of slides of commentary. It's worth reiterating that Codes of Practice are for all Australian industry. Whether it be a sole trader like myself operating out of our study or their garage or something, or whether it be a small operation- a family-run garage or shop, or whether it be the biggest corporation in Australia, whoever that is- if you're running a major mining operation. So, Codes of Practice provide minimum requirements. These are the things that you must comply with. In high-risk industries, you're probably going to have to do a lot more. And they do have a workplace application. So, they are written for the workplace. They're not really written for the designer, manufacturer, importer, supplier, etc. But nevertheless, it is very, very helpful if you are those people to look at the CoP in order to get an idea of what your customers have got to comply with and therefore what you're going to have to supply.

And as I've already said, CoP will repay careful reading because whilst they are guidance, they are really more than guidance. If you are ignorant of CoP and you don't do what they say you are exposing yourself to prosecution. So, see my introduction to Codes of Practice where I talk about that. There are three reasons why you must be aware of Codes of Practice. And this is one of those two Codes of Practice that everyone must be aware of. The others- if you're working with asbestos or welding or whatever it might be then there are specific Codes of Practice that you must be aware of for those activities. But this is one of those ones that applies to absolutely everybody, potentially. And as I've said before, the Model CoP has more detail than maybe some of the regulator-enforced Codes of Practice, which you will, I think, find helpful for higher risk applications. Whether legally you've got an MHF or not.

Commentary #2

And in fact, that's my point in slide two. So, not everyone is required to have a formal safety management system for managing safety risk in a- while something is in service, while it's being used. So, this CoP does not require us to have a formal safety management system, but it is required for major hazard facilities.

#AustralianWHS #CodesofPractice #Consult #Cooperate #Coordinate #coursesafetyengineering #engineersafety #ineedsafety #knowledgeofsafety #learnsafety #needforsafety #safetyblog #safetydo #safetyengineer #safetyengineerskills #safetyengineertraining #safetyengineeringcourse #safetyprinciples #softwaresafety #theneedforsafety #WHSCodeofPractice

Simon Di Nucci

https://www.safetyartisan.com/2020/11/21/consultation-cooperation-coordination-cop/