Comprehensive Project Safety Management Plans: A Guide

Comprehensive Project Safety Management Plans. Safety is a critical element in any large-scale project, especially in the context of defence and complex systems. One essential tool for managing safety is a Safety Management Plan (SMP). In this article, we’ll break down the process and structure of an effective SMP, highlighting its objectives, content, and how to ensure its successful implementation.

Comprehensive Project Safety Management Plans: Introduction

Definitions

A Safety Management Plan is defined as:

“A document that defines the strategy for addressing safety and documents the Safety Management System for a specific project.”UK MoD Defence Standard 00-56

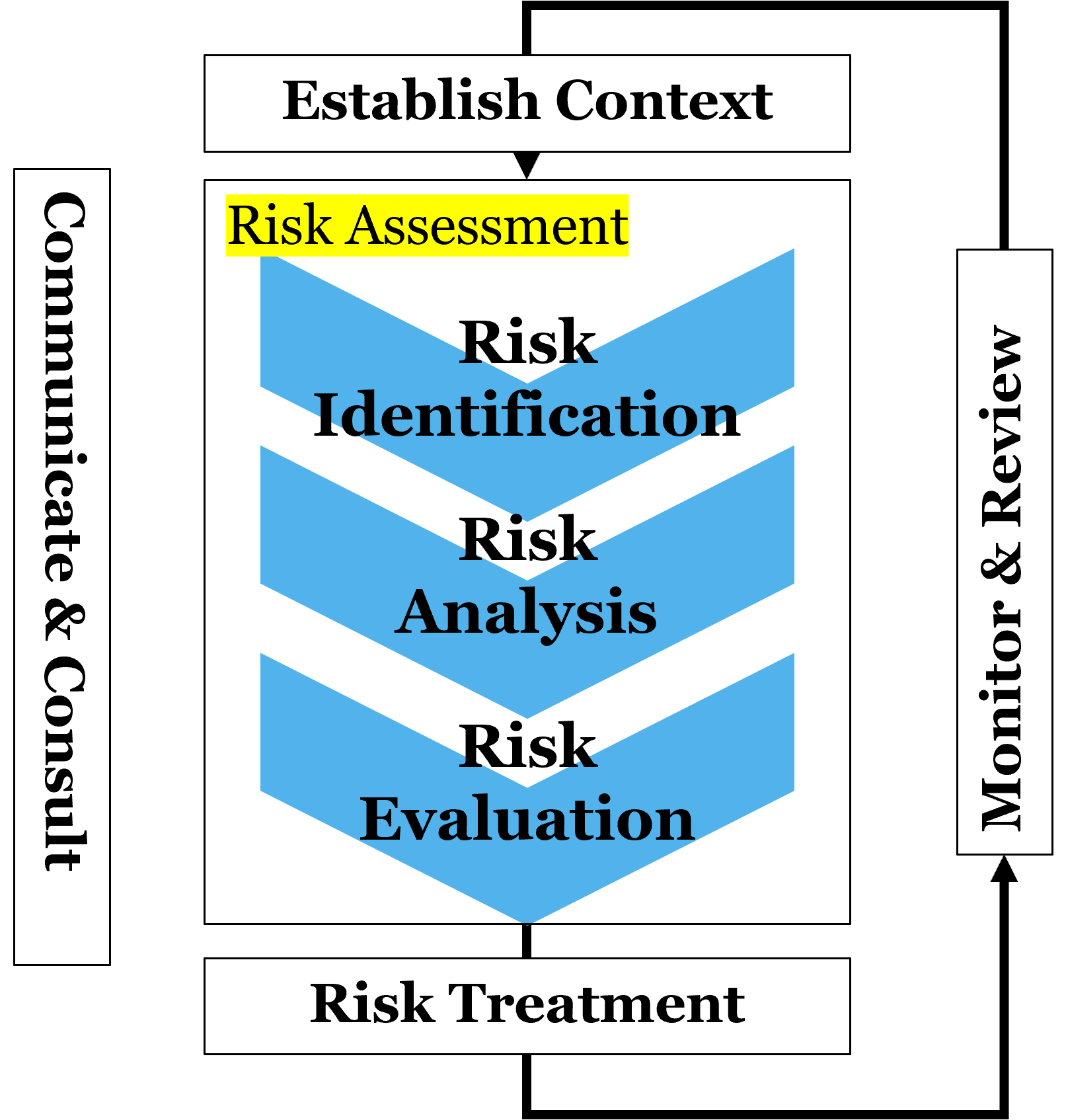

In other words, an SMP serves as a structured approach to managing safety across a project’s lifecycle, ensuring that all risks are identified, analysed, and mitigated effectively.

Objectives

The core objectives of a Project Safety Management Plan are twofold:

- Ensuring Safety Performance: The plan guarantees that the system remains safe throughout its entire lifecycle.

- Maintaining Assurance: It provides the necessary information to demonstrate that safety objectives are being met continuously.

- Achieving these goals requires a coordinated, structured approach that integrates risk management and establishes clear safety requirements right from the start.

SMP in Practice: Contractor vs. Enterprise Project

Each organisation involved in the project—whether it’s the Enterprise Project or a contractor—must produce a distinct SMP that outlines their safety activities. Though separate, these plans should align with each other and the overall project goals. This integration is crucial as safety activities span system development, trials, and any necessary safety approvals.

The SMP discussed here focuses specifically on the Enterprise Project’s plan, which acts as the guiding document for all safety management activities.

Procedure and Methodology

Establishing the Safety Management Framework

The SMP outlines the strategy for ensuring safety and documents the Safety Management System for a particular project. It’s more than just a checklist—it’s a comprehensive program that captures safety timescales, milestones, and other relevant data.

Key areas to be addressed in an SMP include:

- General Equipment Safety: An overarching review of the equipment’s safety features.

- System-Specific Requirements: For example, airworthiness or ship-specific hazards.

- Occupational Safety: Encompassing manual handling, packaging, transport, and more.

- Operational Safety: Ensuring safe procedures during the use phase.

- Maintenance Safety: Guidelines for repair and maintenance activities.

- Training and Disposal: Safety considerations for personnel training and end-of-life disposal of the system.

Creating a Tailored Safety Strategy

No two projects are identical, and neither should their SMPs be. Each plan must be custom-designed to fit the specific project requirements, ensuring a safety strategy that is practical and achievable.

Structuring the SMP: Essential Elements

An effective SMP should contain the following sections:

- Outline Description: Clearly defines the equipment, its purpose, operational environment, and expected capabilities.

- Safety Management System: Details the system’s objectives, managerial tasks, and responsible organisations.

- Responsibilities and Resources: Identifies key personnel and defines their roles through a RACI chart (Responsible, Accountable, Consulted, Informed).

- Audit Arrangements: Outlines internal and independent audit processes.

- Requirements and Acceptance Criteria: Defines safety requirements, targets, and the standards by which success will be measured.

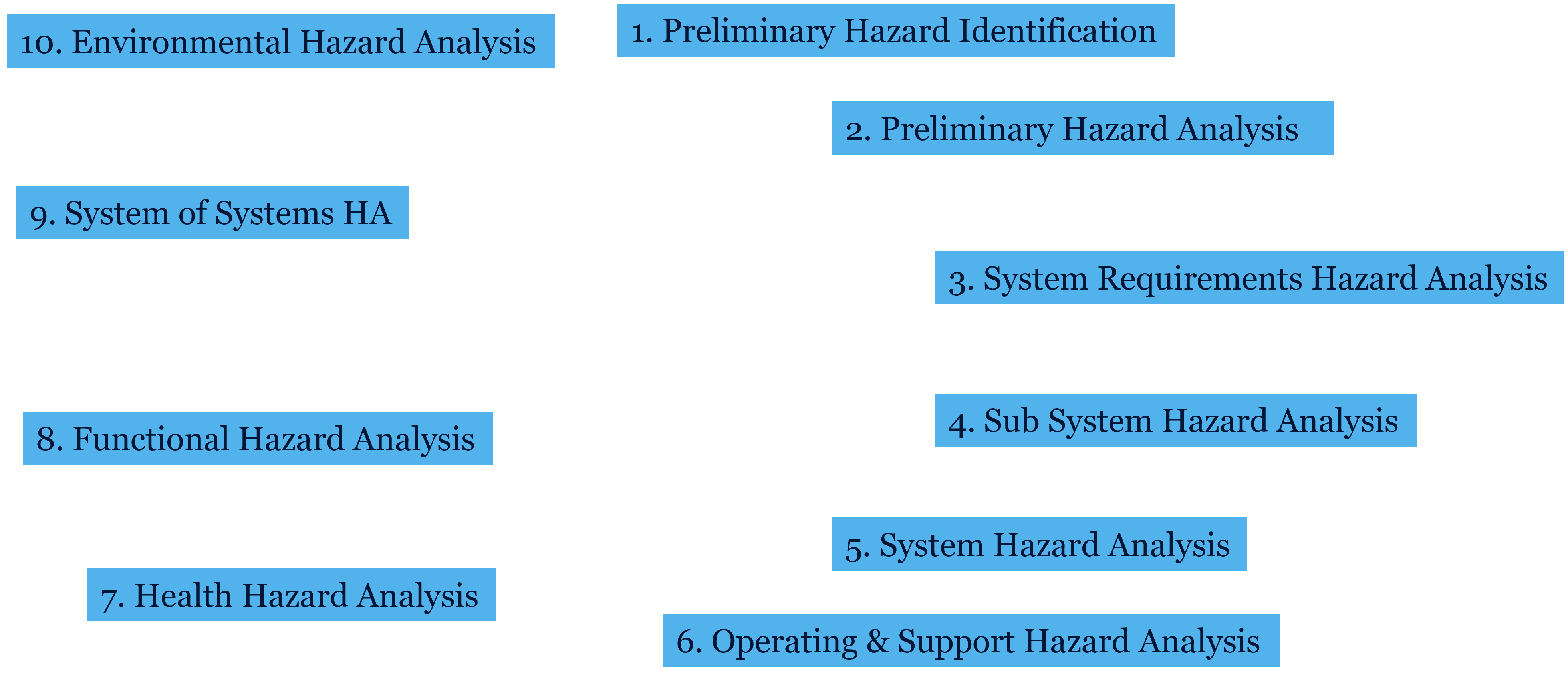

- Safety Case Scope and Strategy: Lays out the assessment strategy and techniques to control hazards.

- Safety Programme: A comprehensive work plan linked to the Through Life Management Plan.

An example template for structuring your SMP can be found in Annexe A. Refer to Annexe B for a sample RACI chart to guide accountability and communication.

Warnings and Potential Project Risks

The SMP is the linchpin of project safety management. If not accurately maintained, the project may face unforeseen delays, increased costs, or compromised safety performance.

Common Pitfalls:

- Inadequate Detail: Missing out on key safety activities can lead to delays and escalated costs.

- Outdated Information: Failing to keep the SMP updated can result in misalignment with the actual safety activities.

- Insufficient Review: Lack of endorsement by the Project Safety Committee (PSC) may mean the plan does not accurately reflect stakeholder responsibilities.

These risks underscore the importance of a thorough, continuously updated SMP.

Procedure Completion and Review

The Project Safety Committee (PSC) is responsible for drafting, endorsing, and reviewing the SMP, ensuring that safety requirements and acceptance criteria are clearly defined and agreed upon by all parties.

Timing:

- Initial Production: Start as early as the Concept stage.

- Ongoing Updates: Review and update the SMP regularly, especially during key project milestones.

The SMP should be a living document that evolves as new information arises or project requirements change.

Safety Planning: Required Inputs

This procedure for Safety Planning requires inputs from:

- Outputs from procedure SMP01 – Safety Initiation;

- Outputs from procedure SMP02 – Safety Committee.

These inputs should be integrated with other management plans throughout the acquisition cycle.

Outputs:

The SMP’s outputs should feed into several project documents, including:

- System Requirements Document: Capture specific safety needs.

- Customer Supplier Agreement: Document mutual agreements on safety deliverables.

- Through Life Management Plan: Align with long-term safety management.

- Business Case Submissions: Support safety-related elements in decision-making processes.

All meeting minutes should reflect decisions made regarding the SMP’s development and upkeep.

Conclusion

The Safety Management Plan is the cornerstone of safety assurance in complex projects. Properly implemented, it serves as a robust framework to manage safety risks, ensure compliance, and maintain confidence in the system’s safety performance throughout its lifecycle.

By following the structure and content outlined in this guide, project teams can create a comprehensive, effective SMP that aligns with the highest standards of safety management.d up-issue.

Safety Planning: Annexe A - Template for a Safety Management Plan

TITLE

Title of equipment or system to be procured with the Requirement reference number.

DESCRIPTION

A brief description of the project, including its purpose and the environment it is to operate in. The scope of the project and interfaces with other equipment are also to be identified.

INVOLVEMENT OF SPECIALIST SAFETY ADVISORS

List any specialist advisors who need to be involved in the program and send them a copy of this plan where required. Such advisers should include internal advisors, external regulators, or statutory bodies that provide advice.

PROJECT SAFETY MANAGEMENT SYSTEM

A description of the Safety Management System within the Enterprise delivery team to include:

- The aims and objectives of the safety management system;

- Technical tasks to be undertaken and the organisation responsible for implementing them;

- Identification of project staff with responsibility for carrying out safety tasks. Include those who are to be issued with letters of delegation;

- Cross-reference to any relevant project safety documents or reports;

- A regime for internal or independent audits of the safety management system;

- Details of the project safety panel;

- Responsibilities, resources, and interfaces with Enterprise, contractor, and specialist advisors;

- Safety reviews, feedback, and reporting procedures;

- Transfer arrangements;

- Design changes;

- Contractor’s trials.

SAFETY REQUIREMENTS

- Safety requirements arising from legislation;

- Enterprise Certification requirements;

- Acceptance criteria;

- Safety requirements from the Requirement or;

- Safety targets;

- Safety-related standards to be applied, e.g. National Standards, Defence Standards, International Standards or overseas standards.

PROGRAMME OF WORK

Identify the tasks that will enable the safety requirements to be met and develop this into a schedule of work on a Gantt or PERT chart, linked to key stages in the Through Life Management Plan.

SAFETY CASE STRATEGY

This strategy should support the program of work above. It will give consideration to the types of analyses and testing to be carried out. It will define the scope of work of the safety case and the interfaces with associated equipment safety cases.

APPROVAL

This plan will be approved by a person with delegated authority.

DISTRIBUTION

Plan to be distributed to the management area with responsibility for in-service support. The plan will also be distributed to teams procuring equipment with which the project interfaces and or interacts.

Annexe B - RACI Chart example

The SMP should contain a RACI Chart to define which authority is Responsible, Accountable, Consulted, or Informed for each of the activities in the Safety Programme. A simple example is given below:

ActivitySafety Delegation HolderProject Safety ManagerIndependent Safety AuditorContractor Project Safety EngineerEquipment UserSafety Case PreparationARIRISafety Case EndorsementAIRIIHazard Log AdministrationAI-R-Safety Requirements PreparationAR-RC

Key: R – Responsible; A – Accountable; C – Consulted; I - Informed

Acknowledgement of Copyright

In this article, I have used material from a UK Ministry of Defence guide, reproduced under the terms of the UK’s Open Government Licence.

Comprehensive Project Safety Management Plans: What are Your Questions?

Meet the Author

Learn safety engineering with me, an industry professional with 25 years of experience. I have:

•Worked on aircraft, ships, submarines, ATMS, trains, and software;

•Tiny programs to some of the biggest (Eurofighter, Future Submarine);

•In the UK and Australia, on US and European programs;

•Taught safety to hundreds of people in the classroom, and thousands online;

•Presented on safety topics at several international conferences.

#functionalsafetymanagementplanexample #gassafetymanagementplan #healthandsafetymanagementplandoc #healthandsafetymanagementplanexample #healthandsafetymanagementplantemplatenz #healthsafetymanagementplantemplate #ohssafetymanagementplan #safetymanagementplandefinition #safetymanagementplanexample #safetymanagementplanforconstruction #safetymanagementplaninmines #safetymanagementplantemplateqld #sitesafetymanagementplanexample #thelifesafetymanagementplanprovidesinformationandguidelinesforwhichofthefollowing #whatisthepurposeofasafetymanagementsystem

Simon Di Nucci https://www.safetyartisan.com/2024/10/16/comprehensive-project-safety-management-plans/